Color masterbatch plays a crucial role in determining the quality and aesthetics of plastic products, especially plastic bags. Many manufacturers face challenges in selecting and evaluating the right masterbatch to ensure durability and safety for consumers. So how can masterbatch quality be controlled before entering production? Eco Plastic will help you find the answer in this article.

1. What is color masterbatch?

Color masterbatch is a concentrated mixture of plastic resin that contains pigments or dyes, a polymer carrier, and special additives. It is used to achieve uniform color in plastic products through blending during production. Masterbatch enables businesses to obtain the desired color while optimizing costs compared to using raw pigments directly.

In plastic bag production, color masterbatch not only affects the visual appeal but also impacts mechanical strength, resistance to environmental factors, and safety in food-contact applications.

What is Color Masterbatch?

2. Why evaluate color masterbatch in plastic bag production?

A high-quality plastic bag is not just about vibrant color. It must also meet requirements for strength, UV resistance, color consistency, and consumer safety. If masterbatch quality is not tightly controlled, final products may fade quickly, tear easily, or fail to meet safety standards. Therefore, evaluating masterbatch before mass production is essential to maintaining brand reputation and customer trust.

3. Key factors in evaluating color masterbatch

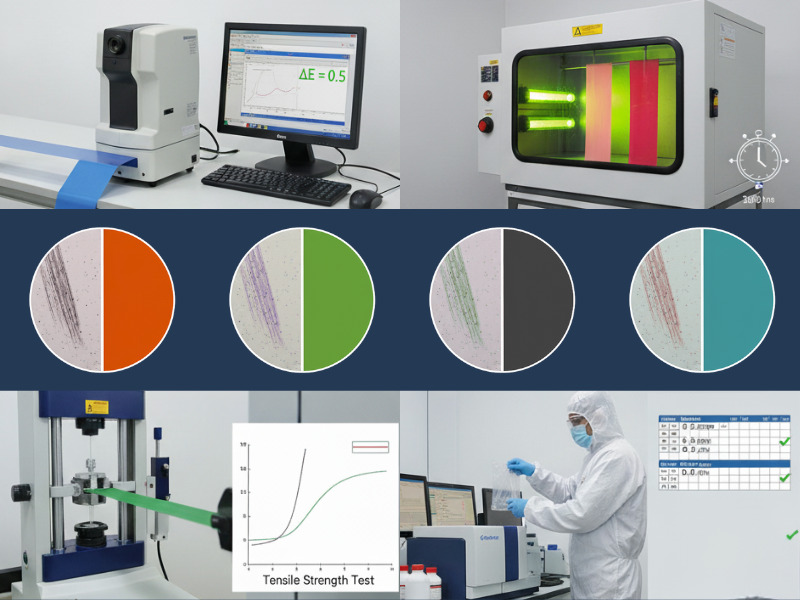

To determine whether a masterbatch is suitable, manufacturers conduct several tests. The following are the most important criteria:

3.1 Color accuracy

Color is the most important factor. Samples are compared with a standard color chart using a spectrophotometer. The color difference (ΔE) must fall within acceptable limits. A low ΔE means the product color closely matches the target, ensuring consistency in plastic bags.

3.2 Colorfastness and resistance to fading

Plastic bags are exposed to sunlight, heat, and friction during use. Masterbatch must retain its color over time. This is tested through artificial aging under UV light or high temperatures. High-quality masterbatch should resist fading, yellowing, or discoloration.

3.3 Dispersion of pigments

If pigments are not evenly dispersed, products will show streaks, specks, or surface defects. Samples are cut and examined under a microscope. Good dispersion ensures a smooth, consistent color without visible flaws.

3.4 Effect on mechanical properties

Besides coloring, masterbatch can influence tensile strength, flexibility, and impact resistance of plastic bags. Tests such as tensile strength and elongation are conducted. A high-quality masterbatch will not weaken the polymer but may even enhance product durability.

3.5 Safety and environmental standards

Plastic bags used in food or medical applications require masterbatch that is free of heavy metals or harmful chemicals. Laboratories test for lead, cadmium, and restricted substances according to international standards. Compliance with REACH, RoHS, or FDA ensures safety and environmental responsibility.

Key Factor in Evaluating Color Masterbatch

4. Quality control process for color masterbatch

The quality control process for color masterbatch usually involves these specific steps:

Step 1: Receiving and analyzing raw material

Samples are first checked for chemical composition to confirm they contain no banned substances, heavy metals, or toxic chemicals.

Step 2: Creating trial samples on a small extruder

Technicians blend masterbatch with base resin to produce test films or sample bags.

Step 3: Color measurement with spectrophotometer

The ΔE color difference is measured to check how closely it matches the standard.

Step 4: Artificial aging tests

Samples are placed under UV light and high temperature to evaluate long-term colorfastness.

Step 5: Mechanical property testing

Tensile strength, elongation, and impact resistance tests ensure masterbatch does not reduce polymer strength.

Step 6: Microscopic observation

Cut samples are examined under a microscope to check pigment dispersion and surface quality.

Step 7: Safety checks and certification

Samples are sent to accredited labs to confirm compliance with REACH, RoHS, or FDA standards. Only masterbatch that passes all these steps is approved for commercial plastic bag production.

Quality Control Process For Color Masterbatch

5. Practical application at Eco Plastic

At Eco Plastic, we always prioritize quality and safety. With a mission to provide eco-friendly and consumer-safe packaging solutions, we only use masterbatch that has undergone rigorous testing. Each batch is verified internally for color stability, mechanical durability, and, when applicable, biodegradability. As a result, Eco Plastic’s plastic bags are not only visually appealing and consistent but also meet international standards for food safety and environmental protection.

6. FAQ

Does color masterbatch affect the recyclability of plastic bags?

Yes. Some masterbatches contain pigments or additives that hinder recycling. However, many suppliers now develop eco-friendly masterbatches that make plastic bags easier to recycle.

How to choose the right color masterbatch for plastic bag production?

Manufacturers should consider product requirements such as color, mechanical durability, UV resistance, and safety standards. Partnering with a trusted supplier like Eco Plastic makes the selection process easier and more reliable.

Conclusion

Evaluating color masterbatch before applying it to plastic bag production is a critical step. A high-quality masterbatch ensures not only aesthetics but also durability, safety, and long-term performance. At Eco Plastic, we place great emphasis on quality control to deliver packaging solutions that are safe, sustainable, and efficient. If you are seeking a reliable partner for high-quality, eco-friendly plastic bags, contact Eco Plastic today for expert consultation.